Video embedded· This is for all the pyro nuts that I came across on Instructables. ... Make a Ball Mill in 5 ... Lead ball for shooting out of black powder .

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale ... ball mill. Also, the effect of powder ... ratio of powder to ball ...

To my knowledge, the effect of mill/ball ratio on ... powder mixtures with 2fold different ball/mill ratios. In this work, I intended to fill the above gap.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

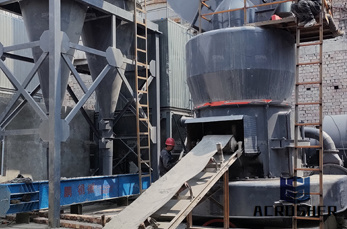

Ball millingthe method of producing manganese metal powder. ... Ball mill has big crushing ratio, simple structure and strong mechanical reliability.

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature

ball and material ratio of ball mill ratio – SAMAC. 7842 USD. Circulating Load Ratio ... ball to powder ratio in ball mill pdf reader | Material processing.

Black Powder Manufacture ... Black Powder MUST be made in a Ball Mill to work properly. A Ball Mill is a rotating drum with dozens of lead balls inside.

Ball Mill The rubber lined ball mil are mainly used for the porcelain powder grinding, ore benefication of metal mine, and nonmetal mineral hill.

Effect of Ball Size and Ball to Powder Ratio Variation on Crystallite Size and Formation of Nanocrystalline Materials in Planetary Ball Mill .

How can I mix two different ceramics powders via ball milling without reducing particles size? ... rotary ball mill ... the balltopowder ratio for ...

A typical ball mill has an L/D ratio of ... However, dry grinding tends to aggregate the powder particles because of the high surface energy of the particles.

Shop huge inventory of Ball Grinding Mill, Ball Mill ... used these for pulverizing cocoa into powder. ... DIM: 53"FB X 89"LR X 86"T. GEAR BOX RATIO: 56 ...

ball mill ball to powder ratio Mining Quarry Plant. ball mill ball to powder ratio . Large crushing ratio. coal mill Coal mill is the equipment which ball to powder ...

Then, the optimal mass ratio of ball to powder in ball mill is *24/(*)= to ... Process engineering of size reduction: ball milling.

ball mill calculations ... ratio of centre distance to mill effective ... and Performs Comparably to Media Manufactured in the Continuous Pin Mill and in Ball Mills ...

Nov 3, 2014 The mill speed, ball to powder ratio, influence is clear. I just wanted Of course that it depends which ceramic material you are milling. Nov 7 .

Jun 21, 2013· Ball to powder ratio: ... A planetary ball mill was employed using a ball to powder weight ratio of 20:1 for various milling time of 5, 10, 15, ...

ball mill design calculation ... Ball Mill Group Calculation Feed capacity → Mill dimensions Filling ratio (3045%), Mill ... design calculations of ball mill ...

best grinding balls for ball mill_ Ceramic Grinding Media ... Best way to determine the balltopowder ratio in ballmilling .

The variation of ball size in a planetary ball mill (PBM) was studied in terms of its effect on the specific impact energy of balls as a result of ball to ball and ...

Why the ball to powder ratio ... is insufficient for describing the mechanical ball milling process. ... The planetary ball mill is one of the most popular and most ...

Ball mill is a key equipment to grind the crushed materials, widely used in the manufacture industries, such as cement, new building material, refractory material and ...

Large crushing ratio. . coal mill Coal mill is the equipment which is used to crush the coal and grind the coal into coal powder. Ball Mill Machine The ball mill .

WhatsApp)

WhatsApp)